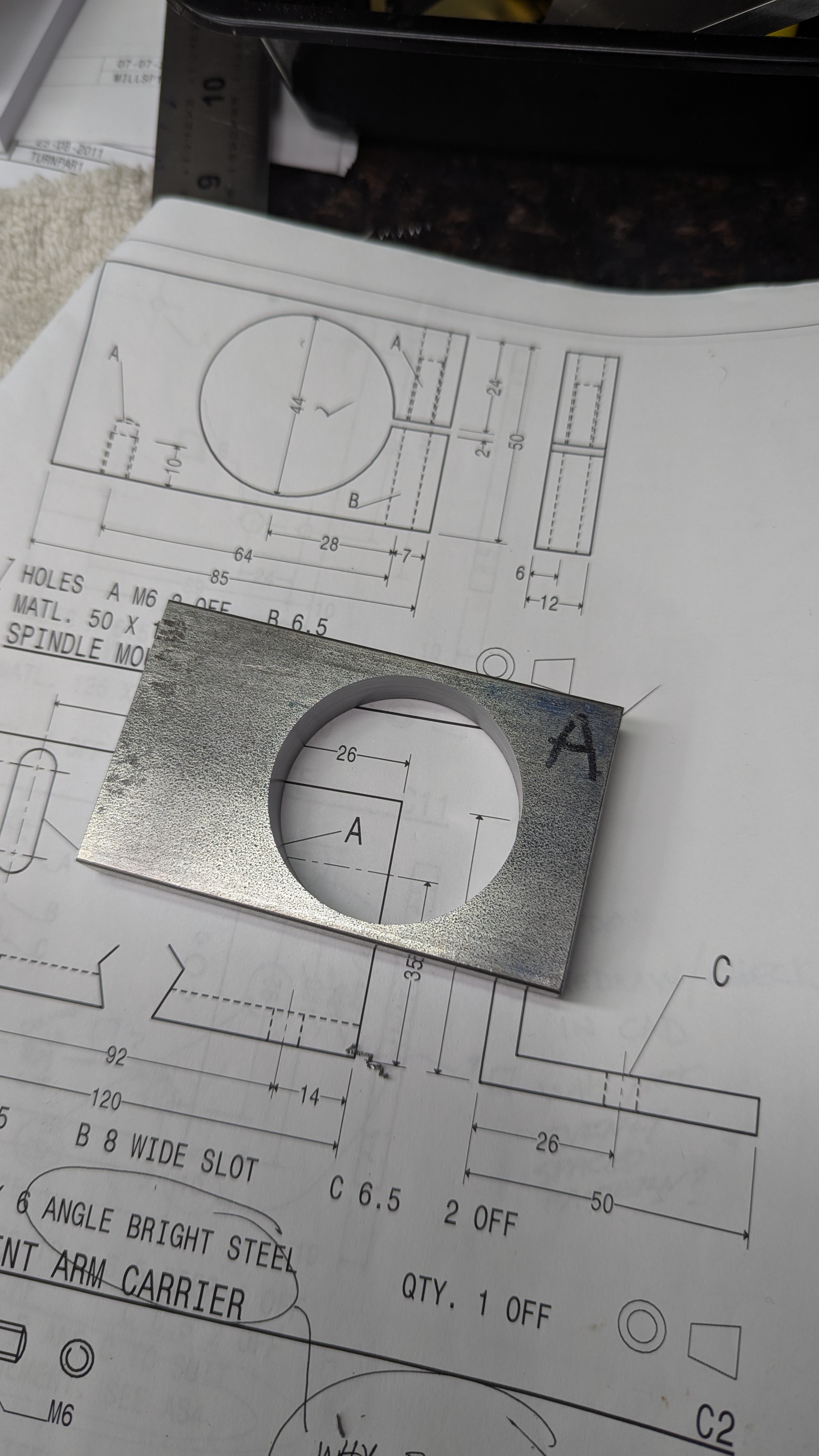

Spindle brackets

Maybe it’s the striving for perfection or perhaps the realization of a near perfect hole. I’m not sure. But there it is, and me smug about it.

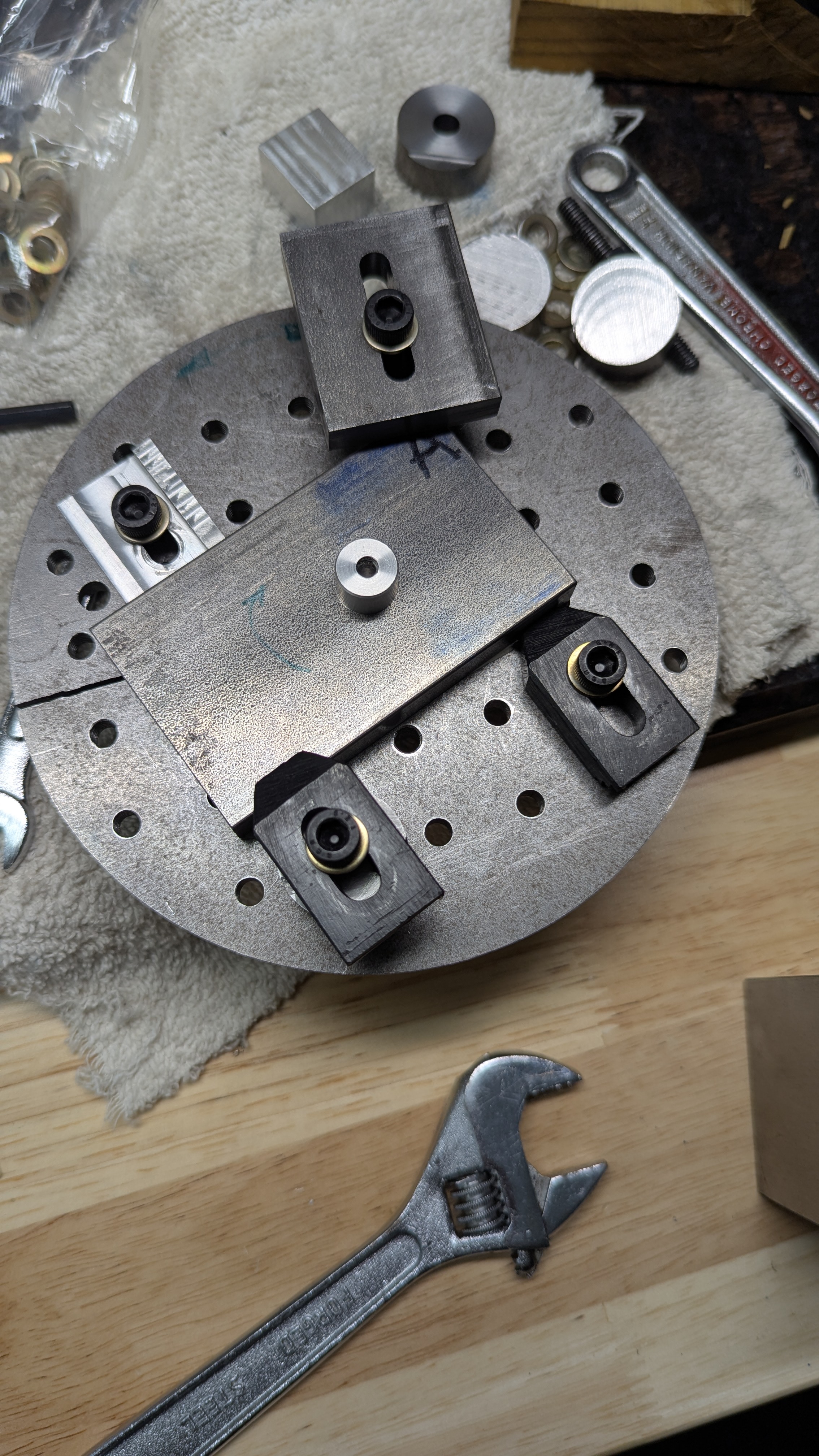

Ok, this should work. Harold Hall is right. Need these things captive.

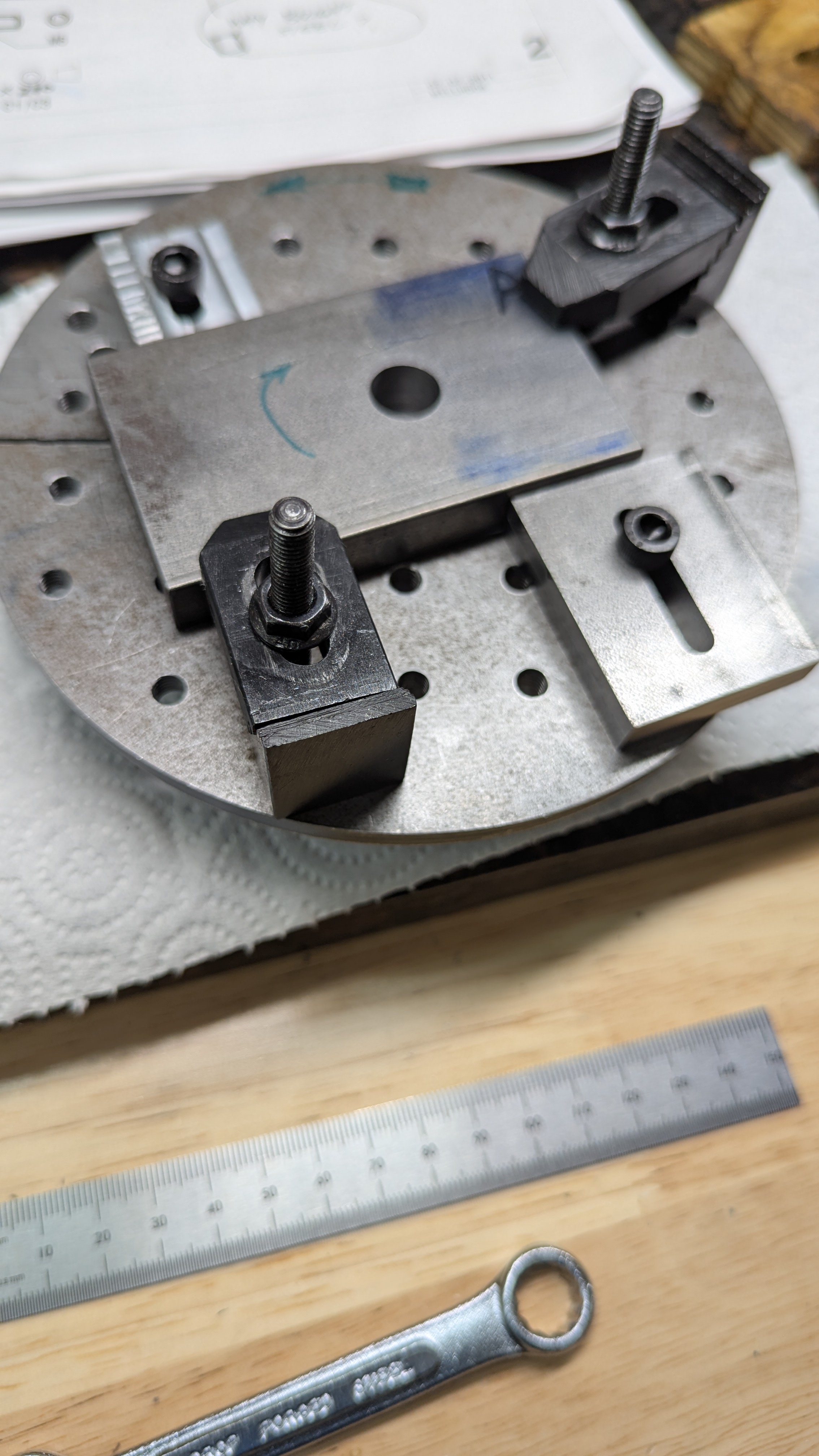

Yea, just not a good idea. Everything needs to be captured/secured. One inadvertent bump and metal starts flying.

Here’s a little look back on what I’ve accomplished since opening shop last year (Late November 2023).

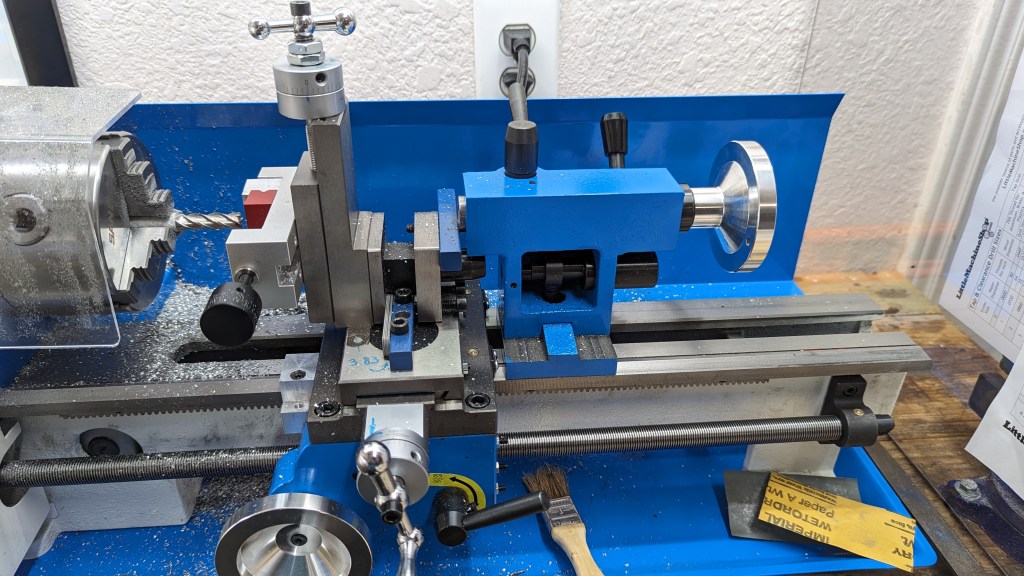

Vevor 7 X 14 mini lathe arrives. It all starts to spiral here…

First project idea. Hey, everyone starts somewhere. 🙂

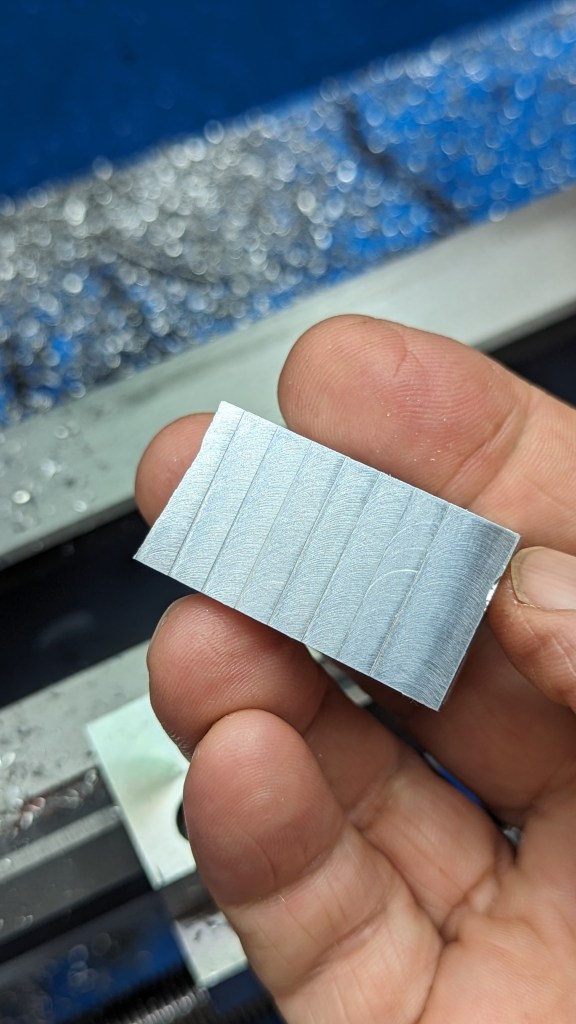

First chips.

Dreaming of making watches. (OK, a little premature.)

All secured and leveled (uh, sort of).

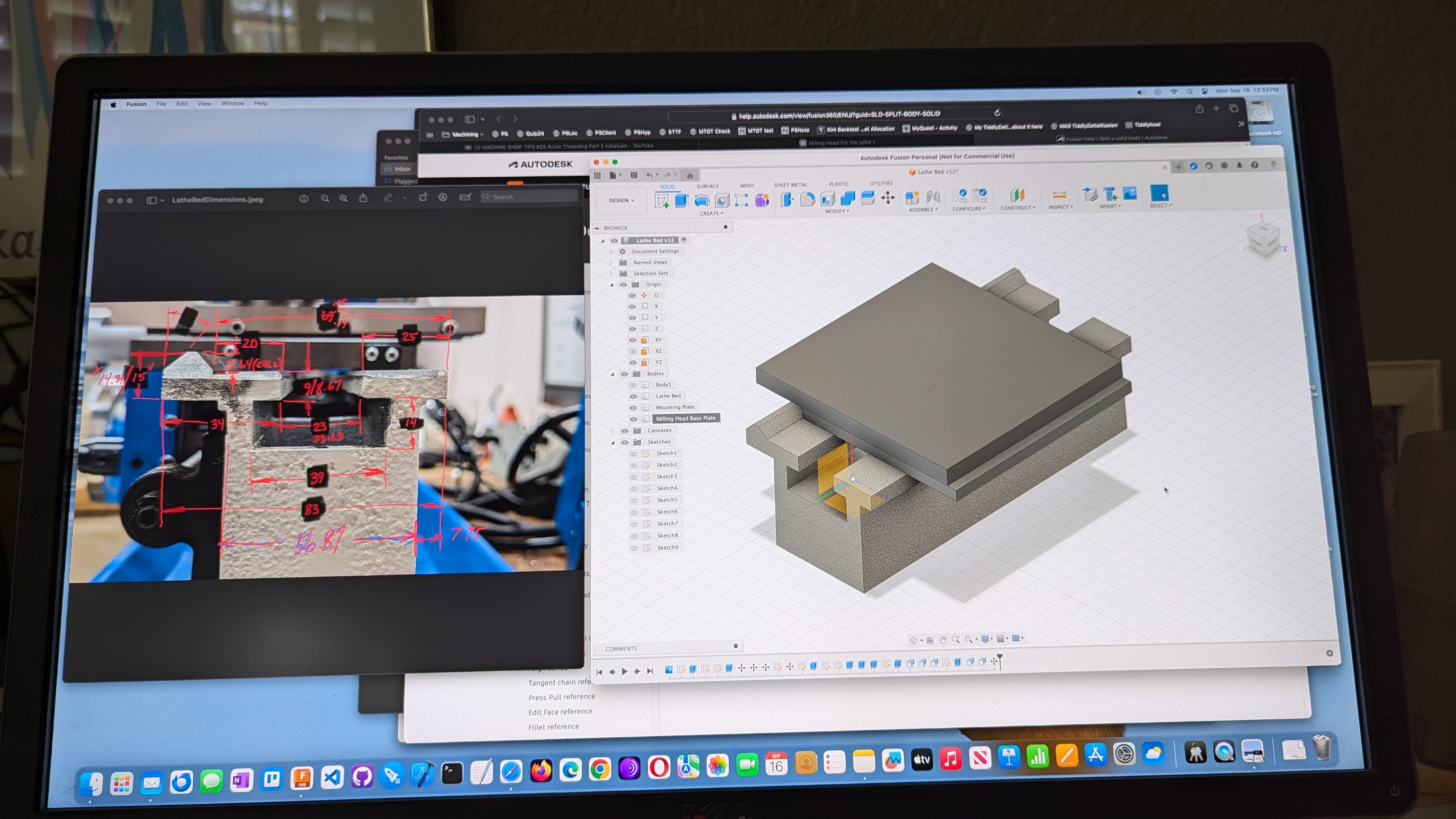

Harold Hall Milling Head (HHMH) – Base – Design

Like many, I only have a mini lathe, but would like to expand my capabilities into milling. There are numerous ways to do this, but I stumbled upon a $0 solution that should work for many mini lathes (I own a Vevor 7 X 14).

It’s easy to implement and, surprisingly, quite rigid. It will cost you nothing (vice optional) if you follow my plan, and the results are, frankly, quite good. 🙂

Here’s a picture of the solution (details coming soon).

Here’s a couple pictures of the results.

Standing up this WordPress blog to support my mini lathe hobby.